Thin Film Solar Panels

Forging Forward With Solar Technology

Thin-film solar panels are the new way forward in solar energy panel technology and its ongoing advancements. No longer must solar panels be large, bulky, crystalline silicon modules; the latest generation of solar panels consists of lightweight, sleek, thin-film panels, marking a major shift in energy technologies. The new high-tech photovoltaic systems employ semiconductor layers that are hundreds of times thinner than traditional solar cells, which are typically 200 nanometers to 4 micrometers thick, compared to silicon wafers, which are typically 200-300 micrometers thick.

This advanced technology bypasses many of the significant drawbacks and limitations of traditional solar panels, including weight restrictions, installation complexity, and aesthetic concerns. As a result, it opens up new and better markets that were previously unavailable with the old traditional system. Thin film solar panels used nowadays strike a balance between high portability and flexible installation methods, allowing solar power generation from diverse sources, including flexible surfaces and now wearable devices.

What "Thin Film" Means in Solar

The term “thin film” in the context of solar technology refers to photovoltaic cells constructed with extremely thin layers of light-absorbing material that are deposited onto substrates such as glass, plastic, or metal foils.

One defining characteristic of the material is the thickness difference between the ultra-thin film layers, which range from 0.2 to 4 micrometers, and crystalline silicon cells, which are typically between 200 and 300 micrometers. The architecture of this ultra-thin film gives it unique properties, including flexibility, reduced weight, and significantly lower material usage during manufacturing.

The choice of substrate determines the final characteristics, with glass providing hardness for traditional installations while flexible substrates allow bending and mobility. Unlike conventional solar panels, which require energy-intensive silicon purification and wafer cutting, thin film technology permits photovoltaic materials to be deposited directly through various methods, including chemical vapor deposition, sputtering, and solution processing. This difference in construction and manufacture presents huge opportunities for innovative applications, while also simplifying the manufacturing process and reducing the cost of raw materials.

How Perovskite Thin Films Are Manufactured

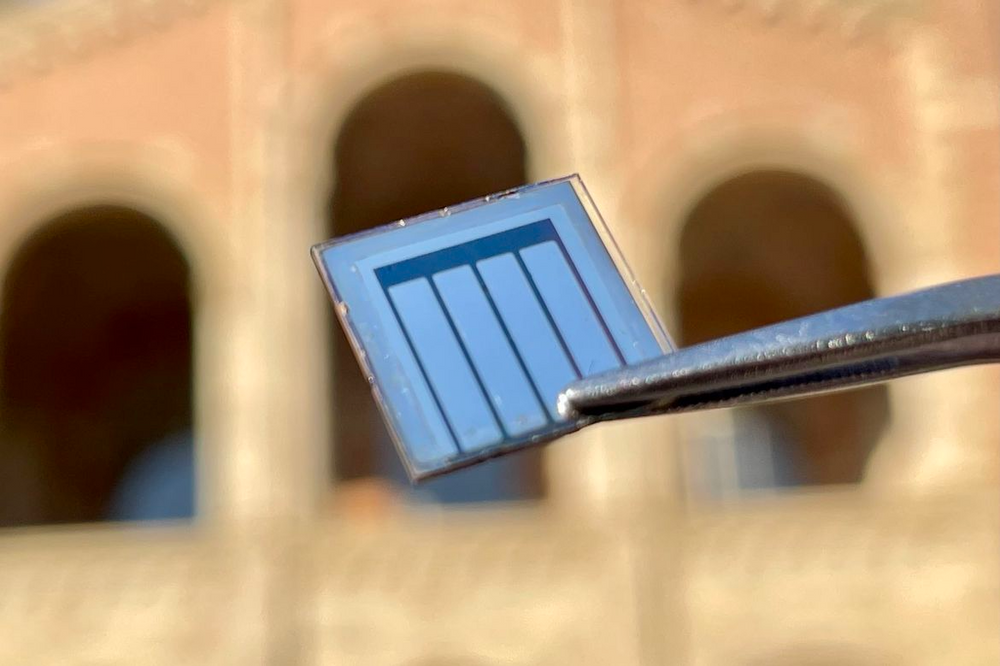

Perovskite thin film fabrication is α cutting-edge solar technology process that uses new solution-based methods. Each method is different and offers major advantages over traditional practices. Fabrication begins with the mixing of precursor salts, which then form perovskite ink solutions. In cases of vapor deposition, the salts are stored separately until they are collectively deposited on the cell substrate.

Think of the perovskite solar cell technology as a thin-film photovoltaic technology, where fixed or flexible solar cells are fabricated using 0.2-0.4 μm. They are thinner than classical thin-film solar cells, with layers ranging from 0.5 to 1 μm. Fabrication involves various state-of-the-art deposition techniques, including spin coating, slot-die coating, blade coating, spray coating, inkjet printing, screen printing, and vapor deposition processes, each optimized for specific scales and applications.

The multi-layer design features transparent conductive oxide layers that serve as electrical contacts, electron and hole transport layers for efficient charge collection, and protective metal oxide layers for long-term stability. This low-temperature process, combined with the solution-deposition-based scalable manufacturing process, makes perovskite technology extremely sought after for mass production without compromising its high efficiency levels.

Advantages of Thin Film Solar Panels

Widespread real-world testing has proven thin-film solar technology panel performance under wide-ranging applications and conditions.

Large-scale fabrication processes for ultrathin, flexible, rugged, and lightweight solar cells have been recently developed by MIT researchers, allowing them to adhere to any surface. When mounted on high-strength fabric, the cells weigh one-hundredth as much as conventional cells but produce eighteen times as much power per kilogram. This superior power-to-weight ratio is ideal for aerospace and portable applications.

Testing in the field has revealed consistent performance in partial shading, where the thin-film panels have reliably outperformed their crystalline silicon counterparts due to their uniform light absorption characteristics.

Temperature coefficient testing shows improved hot weather performance, with thin film maintaining high efficiency solar as temperatures rise compared to traditional silicon panels that experience severe degradation.

Finally, spectral response testing demonstrates thin film panels' ability to absorb sunlight at preferred wavelengths or much shorter wavelengths than silicon cells. Shorter wavelengths provide higher energy absorption, making it easier to convert to electricity.

Real-World Performance & Testing

Durability has long been a significant issue with flexible solar panels, but advances in materials science over the years have addressed many of these problems. CPTI's perovskite solar technology boasts a lifetime over ten times longer than earlier flexible solar technologies, demonstrating significant improvements in both longevity and stability.

Performance testing of flexible solar cells presents unique challenges compared to rigid panels. Mechanical stress testing includes cyclic bending, twist testing, and impact resistance testing. These tests verify that the cells maintain their electrical properties under certain mechanical stresses they may be subjected to in real-world use.

Then, there’s environmental durability testing. Flexible solar cells must withstand temperature cycling, exposure to humidity, and UV radiation without degradation of performance. CPTI designs every layer for maximum stability and performance to make sure that our flexible cells remain long-lasting in adverse environmental conditions.

Integration & Applications

Thanks to the design of thin-film solar panels, along with their flexibility, you can integrate them into previously unimaginable applications, thereby extending solar deployment into new markets.

Building-integrated photovoltaics gives the world massive new opportunities, including panels that seamlessly integrate into roofs, windows, and facade materials. These harvest free and clean energy without compromising appearance, making energy much less expensive.

Since panels can be curved to fit any type of vehicle surface, automotive applications range from auxiliary power units for electric vehicles to solar-powered ventilation systems. Applications in aerospace include high power-to-weight ratios for use in satellite power supplies, high-altitude air platforms, and unmanned aerial vehicles, where weight is severely limited.

Thin-film solar panels are corrosion-resistant and flexible, allowing for integration into sails, deck surfaces, and portable marine electronics. Additionally, there are industrial applications where they can provide remote monitoring systems, pipeline sensors, and telecommunications equipment, particularly in areas where grid connection is not possible.

Finally, integrating them into consumer electronics provides sustainability for products such as smart sensors, wearable gadgets, and portable charging systems. You can finally free your products from the age-old dependence on batteries by harnessing ambient light.

Transform Your Products with CPTI Thin Film Panels

CPTI's perovskite thin film technology has immediate potential for next-generation solar solutions across an extensive range of applications. CPTI's proprietary and innovative multi-layer design includes optimized transport layers, transparent conductive oxides, and protective coatings that maximize efficiency and lifetime in thin film structures.

Production and manufacture are carried out using scalable solution deposition processes. This results in low-cost manufacturing and consistent quality across diverse substrate types and panel sizes.

Key technical features include industry-leading power-to-weight ratios, exceptional low-light solar panel performance, and improved temperature coefficients that provide quantifiable advantages over current technology.

We can help you deploy thin-film panels in several ways, from comprehensive application engineering to performance modeling and integration services. We further support your needs with extensive quality assurance programs that demonstrate actual in-use performance and long-term durability.

Our product portfolio caters to diverse requirements, ranging from rigid glass-substrate panels for traditional installations to flexible panels for applications on curved surfaces and mobile use. Contact us today and see how our thin-film panels can transform your business!